In depth knowledge of our machines and their potential has led us to look for a production method which obtains the maximum performance from each type of metalworking and satisfies every need our customers may have.

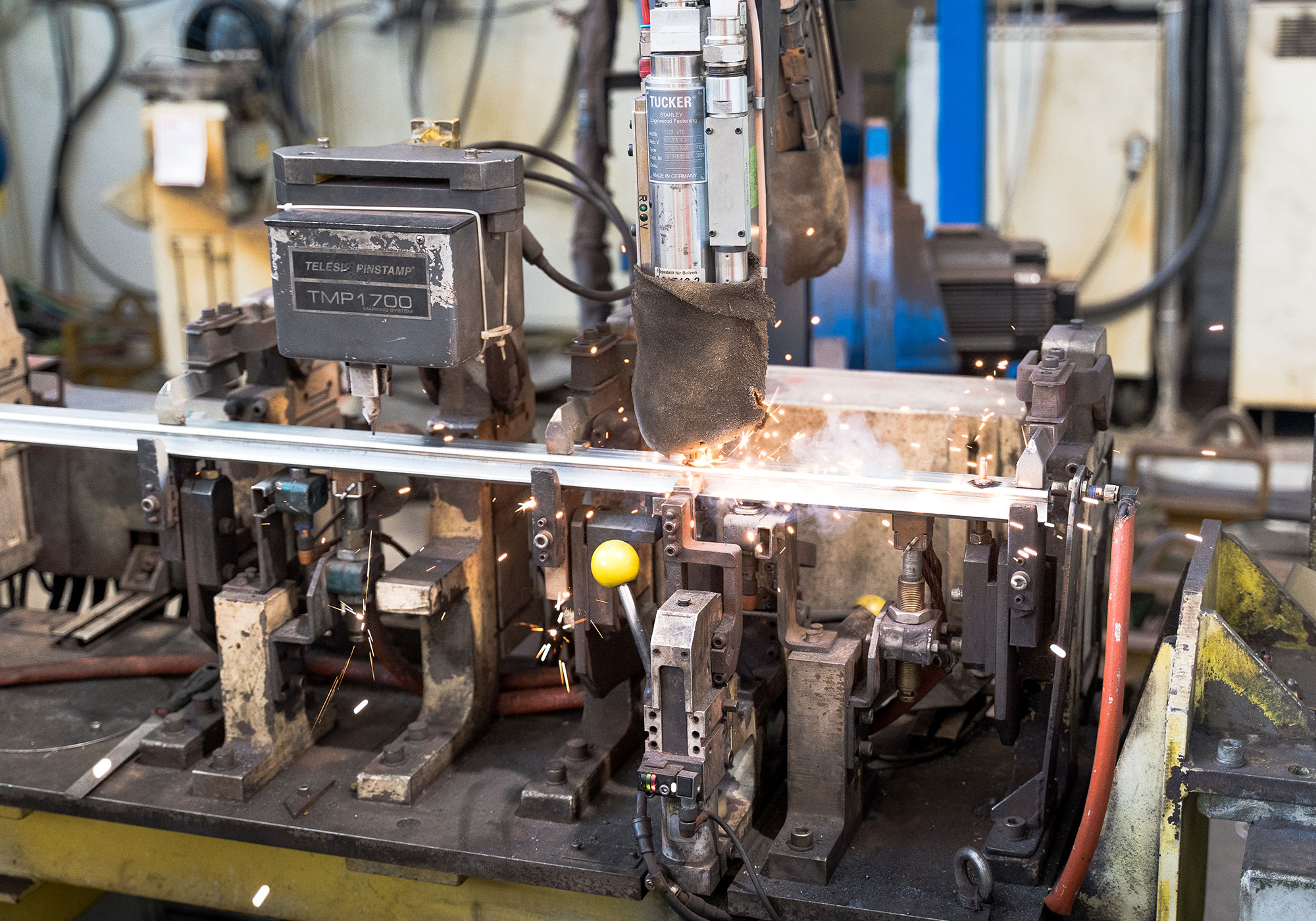

In this way the “integrated processes” were born. The machines are placed in sequence, according to the type of geometry which is desired, avoiding intermediate steps and stocking. In this way we assure greater efficiency and improve the quality characteristics, being able to achieve complex geometries.

Another advantage is the interchangeability of tooling: the sequence of the machines remains unchanged and the intervention is limited to a change of tooling as necessary. In this way there is also an optimization of the time spent on updating the production line, reducing waiting and set-up times.